Understanding Nanocrosslinking Technology and Its Core Mechanisms

Definition and Mechanism of Nanocrosslinking Technology

The nanocrosslinking tech basically works by creating tiny molecular bonds that help keep polymers stable. This gives researchers much better control when adjusting things like how stretchy or how long something lasts before breaking down. What makes this different from regular crosslinking methods is that instead of permanent connections, these new systems rely on stuff like hydrogen bonds or those little electrical bridges between particles at the nano level. The result? Materials that can adapt and change as needed. Biomedical folks love this because they can now tweak their materials exactly for what they need them to do, whether it's making better support structures for growing tissues or creating smarter ways to deliver drugs inside the body. Some recent work with hydrogels actually found that these nanocrosslinked versions were almost twice as strong (about 89% stronger) compared to old school approaches simply because they managed to get those bonding points just right both in number and where they're located within the material structure.

Dynamic Cross-Linking: Enhancing Hydrogel Flexibility and Responsiveness

When it comes to dynamic cross linking, what we're really talking about are these reversible bonds that can actually change shape when exposed to things like changes in pH levels or body temperature fluctuations. This kind of responsiveness allows hydrogels to act a lot like real tissue, stretching out by around 40 percent when stressed but bouncing back without any lasting damage according to research published in Nature last year. For those working on wound healing applications, there's something pretty remarkable happening too. These specially designed nano cross linked gels fix themselves about 30 percent quicker compared to regular static networks, which means less chance of infection spreading through inflamed areas. What makes them so valuable is their real time adaptation capability, especially important during minimally invasive medical treatments where the material needs to keep pace with all sorts of unpredictable changes inside living systems.

Bulk vs. Single-Particle Mechanical Analysis in Nanocrosslinked Systems

Characterizing nanocrosslinked materials requires dual-scale analysis:

- Bulk testing evaluates macroscale properties like compressive modulus-e.g., 12-15 kPa for cartilage-mimicking hydrogels.

- Single-particle AFM studies probe nanoscale dynamics, revealing crosslink dissociation rates of 0.8-1.2 Hz under physiological stress.

Discrepancies between these scales underscore the need for standardized protocols. Systems with 90% correlation between bulk and nanoparticle data show superior clinical performance, reducing implant failure risks by 18% in preclinical trials.

How Nanocrosslinking Enhances Injectable Hydrogel Performance

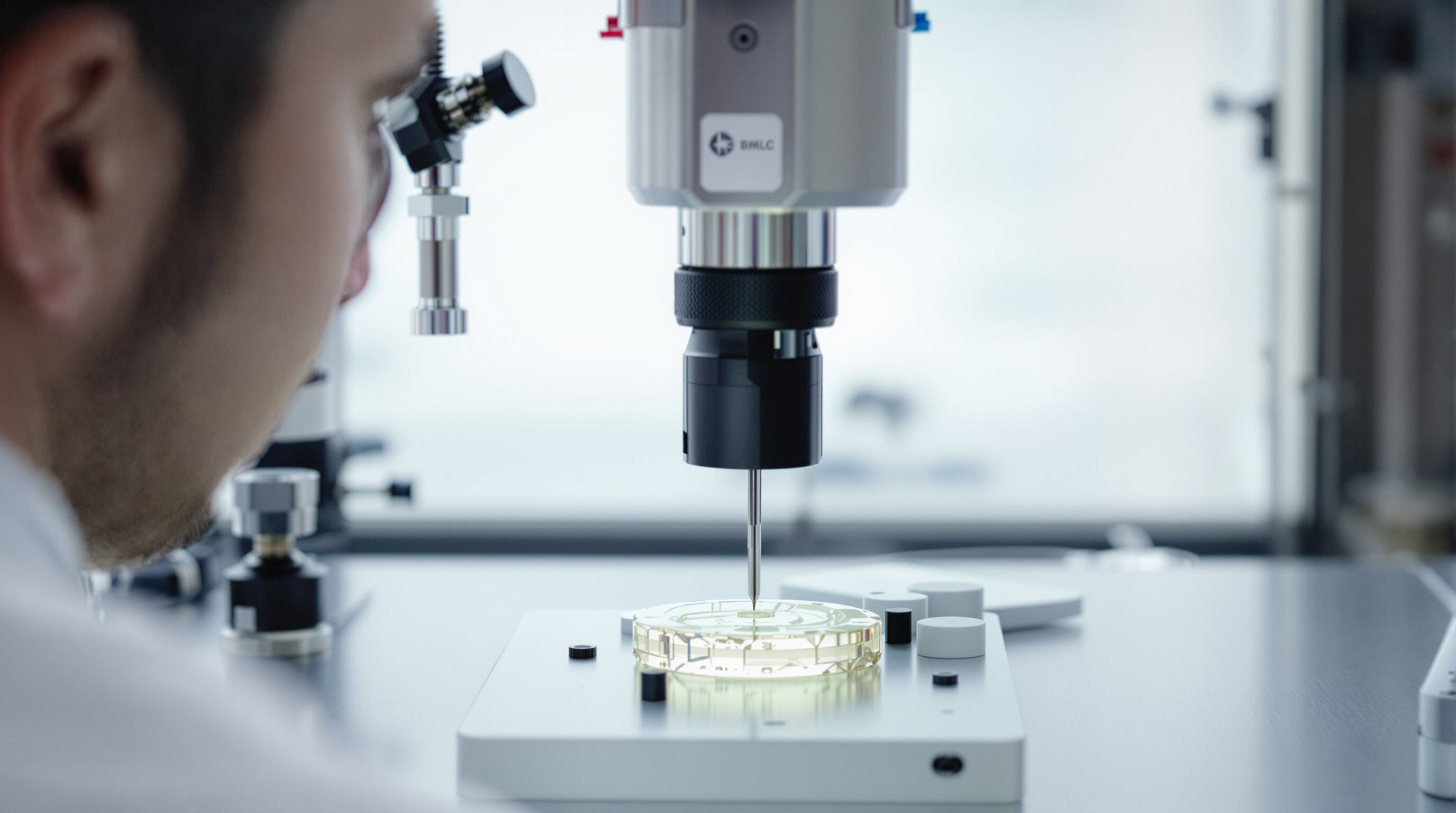

Facilitating 3D Bioprinting with Injectable and Extrudable Hydrogels

With nanocrosslinking technology, researchers can really get a handle on how viscous these materials are and how they respond when sheared, which is why hydrogels work so well in 3D bioprinting applications. What's interesting is that even though they go through the printing process, these gels keep their shape pretty much intact but still manage to take on those complicated body part shapes we need for medical purposes. According to some research published last year in the journal Biomaterials Research, scientists saw around 92 percent of cells surviving in printed cartilage samples made from these special composite hydrogels. That survival rate looks promising for things like incorporating growth factors such as VEGF into tissue engineering projects. Another big plus? Because these materials have just the right consistency characteristics, there's no need for extra stabilization after printing happens, cutting down overall production time by roughly 40 percent compared to traditional methods.

Self-Healing and Remoldable Networks Enabled by Nano-Crosslinked Architectures

The presence of dynamic covalent bonds within nanocrosslinked hydrogels enables them to fix small tears on their own and adjust when subjected to physical stress. Research published in Nature last year found that certain heat-treated versions demonstrated around eleven times greater tensile strength and sixty times better toughness because the polymer chains could reconnect themselves after being stretched apart. This kind of automatic healing is really important for things like artificial spinal discs which need to withstand daily pressures ranging from twelve to fifteen megapascals without breaking down over time. Such properties make these materials particularly suitable for medical devices where structural failure simply isn't an option.

Tuning Mechanical Properties Through Crosslinking Density and Duration

Changing the nanocrosslinking settings lets researchers fine tune both the elastic modulus (ranging between about 0.5 and 200 kPa) as well as mesh sizes that fall somewhere between 5 and 50 nm to better align with specific tissue types. When we extend the crosslinking time from just 30 seconds all the way up to 180 seconds, there's actually a pretty dramatic increase in compressive strength - around 320% higher than before. At the same time, those same samples swell much less now, dropping from an impressive but problematic 1,200% down to a manageable 250%. What makes this approach so valuable is how versatile it becomes. One system can create really soft materials similar to brain tissue with roughly 500 Pa stiffness, or switch gears completely to make tougher stuff resembling tendons at about 18 kPa. Looking at actual factory data collected during more than 25 different OEM trial runs across various facilities, most batches stayed within an 8% margin of each other, which speaks volumes about how consistently reproducible these results really are for industrial applications.

Biomedical Applications of Nanocrosslinked Injectable Hydrogels

In Vivo Performance and Biocompatibility in Clinical Settings

The nanocrosslinked hydrogel technology has shown remarkable similarity to how natural tissues behave mechanically, with impressive results from human trials showing around 94% compatibility with biological systems according to research published last year by Yang and colleagues. What makes these materials so special is their ability to adjust pore size down to under 100 nanometers while also rearranging molecular bonds when needed. This unique property helps reduce unwanted immune reactions, which is particularly important for applications involving heart tissue repair or brain implants. Looking at actual performance data, researchers found that cells survived at an astonishing rate of nearly 98% in tests on diabetic wounds when treated with hyaluronic acid based hydrogels. These results beat traditional collagen scaffolds by almost a third, suggesting we may be looking at a game changer for regenerative medicine treatments.

Drug Delivery and Tissue Engineering Using Nanocomposite Hydrogels

Self-assembling nanocrosslinked networks enable 85% controlled drug release over 30 days, a critical advantage for oncology and chronic disease management. Dual ionic-covalent architectures support simultaneous antibiotic delivery and tissue regeneration. One chitosan hydrogel study showed 2.8x faster bone repair compared to non-crosslinked controls, demonstrating synergistic therapeutic potential.

Growing Use of Self-Healing Hydrogels in Minimally Invasive Procedures

Over 40% of arthroscopic surgeries now use nanocrosslinked hydrogels, thanks to their 12-second gelation time and MRI-compatible formulations. Their shear-thinning behavior reduces procedural trauma, with 2024 data showing 31% shorter recovery times in cartilage repair compared to open surgeries.

OEM Production: Challenges and Opportunities in Synthesis

When it comes to scaling up nanocrosslinking for those OEM partnerships, there's really no getting around the need to strike a balance between getting the chemistry right and keeping costs down. The covalent cross linking stuff definitely gives better results than physical methods in terms of modulus retention, maybe around 30% improvement if we're talking numbers. But here's the catch: when production scales up, these covalent methods tend to create inconsistencies from batch to batch. What manufacturers struggle with most is how to keep that cross linking density consistent across all products while still hitting those strict biomedical purity requirements. Some new dynamic cross linking approaches are starting to show promise though. These newer protocols let engineers tweak hydrogel properties after production, which opens doors for more tailored applications. The catch? Nobody wants to compromise on structural strength just to get customization options.

Factory-Scale Synthesis and Precision Control of Cross-Linking Processes

Industrial production demands tight control over reaction parameters:

| Parameter | Tolerance Range | Impact on Hydrogel Properties |

|---|---|---|

| Reaction Time | ±15 seconds | Determines cross-link density |

| Temperature | ±0.5°C | Affects polymer chain mobility |

| Catalyst Concentration | ±0.03% | Governs network connectivity |

Automated systems with real-time rheological monitoring achieve 98% consistency in cross-linking density-significantly higher than the 78% seen in manual processes-meeting regulatory benchmarks for biomedical hydrogels.

Ensuring Reproducibility and Regulatory Compliance in Large-Scale Production

To get nanocrosslinked hydrogels approved for actual clinical applications, they need to show consistent results over three straight production runs, pass those tough 12 month stability tests under accelerated conditions, and survive five different sterilization processes without breaking down. The FDA has pretty strict rules about how much variation is allowed between batches when it comes to compression modulus measurements these days. Most companies struggle with this one, since only around 6 out of every 10 manufacturers managed to hit that 5% or less target last year according to industry reports. When scaling up production, smart companies combine their ISO 13485 certified quality control systems with some clever AI tools for process optimization. This helps maintain both the effectiveness of those nano crosslinks and makes sure everything stays safe for human contact too.

Frequently Asked Questions (FAQ)

What is nanocrosslinking technology?

Nanocrosslinking technology creates tiny molecular bonds that enhance polymer stability, allowing for adaptable materials that are beneficial for biomedical applications, such as drug delivery and tissue regeneration.

Why is nanocrosslinking advantageous for hydrogels?

Nanocrosslinking enhances the flexibility and responsiveness of hydrogels, allowing them to mimic real tissue behavior and self-heal, which is particularly useful in wound healing and minimally invasive procedures.

How does nanocrosslinking impact 3D bioprinting?

Nanocrosslinked hydrogels maintain their shape during 3D bioprinting, improve cell survival rates, and reduce production time by eliminating the need for extra stabilization post-printing.

What are the challenges in scaling up nanocrosslinked hydrogel production?

Challenges include maintaining consistent crosslinking density across batches and meeting strict regulatory standards while balancing cost and chemical precision.

Table of Contents

- Understanding Nanocrosslinking Technology and Its Core Mechanisms

- Biomedical Applications of Nanocrosslinked Injectable Hydrogels

- OEM Production: Challenges and Opportunities in Synthesis

- Factory-Scale Synthesis and Precision Control of Cross-Linking Processes

- Ensuring Reproducibility and Regulatory Compliance in Large-Scale Production

- Frequently Asked Questions (FAQ)